In industries where transporting abrasive slurries is a daily necessity—such as mining, dredging, and wastewater treatment—the right pump can make the difference between operational success and costly downtime. At Denver Pumps, we specialize in providing robust, efficient, and durable solutions tailored to handle the toughest abrasive slurry applications.

What Is an Abrasive Slurry Pump?

An abrasive slurry pump is engineered to move mixtures of liquid and solid particles, often found in mining, dredging, and industrial processes. These pumps are designed to withstand the wear and tear caused by abrasive materials like sand, gravel, and mineral particles, ensuring longevity and reliability in harsh environments.

Why Abrasive Slurry Pumps Matter

In industries handling abrasive slurries, equipment durability and efficiency are paramount. Abrasive slurry pumps are critical for:

- Reducing Downtime: Minimizing maintenance and unexpected failures.

- Enhancing Efficiency: Ensuring consistent flow rates and pressure.

- Lowering Operational Costs: Extending equipment lifespan reduces replacement and repair expenses.

Selecting the appropriate pump ensures optimal performance and cost-effectiveness in demanding applications.

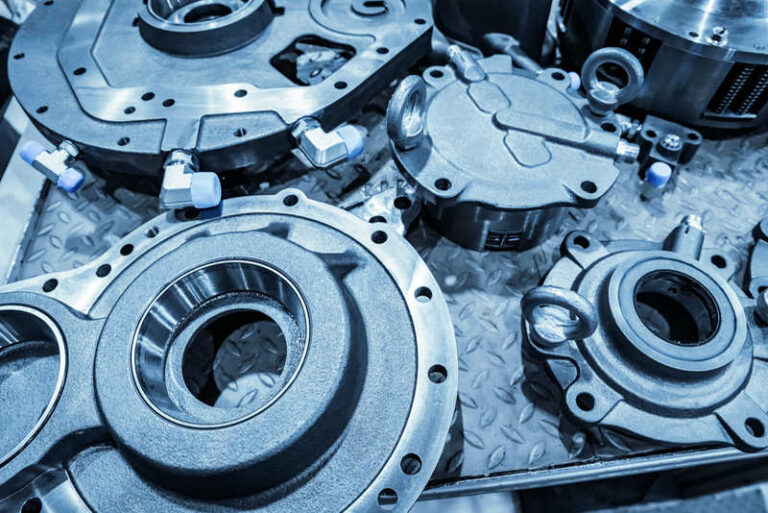

Key Features of Abrasive Slurry Pumps

To handle abrasive materials effectively, these pumps incorporate:

Wear-Resistant Materials: Utilizing high-chrome alloys, rubber linings, or ceramic components to resist abrasion.

Robust Design: Heavy-duty construction to withstand high pressures and impact from solid particles.

Efficient Sealing Systems: Preventing leakage and protecting internal components from wear.

Adjustable Impellers: Allowing for performance tuning and compensation for wear over time.

Applications of Abrasive Slurry Pumps

These pumps are vital in various sectors:

Chemical Processing: Managing corrosive and abrasive chemical mixtures.

Mining: Transporting mineral slurries, tailings, and ore concentrates.

Dredging: Removing sediments and debris from water bodies.

Wastewater Treatment: Handling sludge and grit removal processes.

Construction: Pumping bentonite slurries for tunneling and foundation work.

Industry Trends and Statistics

The abrasive slurry pump market is evolving with technological advancements and increasing demand:

Smart Monitoring: Adoption of IoT and sensor technologies enables real-time performance tracking and predictive maintenance.

Market Growth: The global slurry pumps market is projected to reach USD 1.93 billion by 2030, growing at a CAGR of 4.88% from 2025.

Material Innovations: Development of advanced materials like high-chrome alloys and ceramics enhances pump durability.

Energy Efficiency: Integration of variable frequency drives (VFDs) and efficient hydraulic designs reduces energy consumption.

FAQs About Abrasive Slurry Pumps

What causes rapid wear in slurry pumps?

The presence of hard, abrasive particles in the slurry leads to erosion of pump components, especially if the pump is not designed with wear-resistant materials.

How can I extend the lifespan of my slurry pump?

Regular maintenance, using pumps with wear-resistant materials, operating at optimal speeds, and implementing predictive monitoring can significantly extend pump life.

Are there energy-efficient slurry pumps?

Yes, modern slurry pumps incorporate energy-saving features like VFDs and optimized impeller designs to reduce power consumption.

Can slurry pumps handle corrosive materials?

Specialized slurry pumps made with corrosion-resistant materials like certain stainless steels or coatings are designed to handle corrosive slurries.

What maintenance practices are recommended?

Regular inspection of wear parts, timely replacement of liners and impellers, monitoring vibration and temperature, and ensuring proper lubrication are key maintenance practices.

Why Choose Denver Pumps for Abrasive Slurry Applications

At Denver Pumps, we offer:

Comprehensive Support: From installation to maintenance, we provide end-to-end support to ensure optimal pump performance.

Expertise: Decades of experience in selecting and servicing slurry pumps for various industries.

Customized Solutions: Tailored pump selections to match specific application requirements.

Quality Products: Access to leading manufacturers and high-quality, durable pump options.

Abrasive slurry pumps are essential in industries where transporting mixtures of liquids and solids is routine. Understanding their design, applications, and maintenance is crucial for operational efficiency and cost savings. Denver Pumps is committed to providing expert guidance and high-quality solutions for all your abrasive slurry pumping needs.