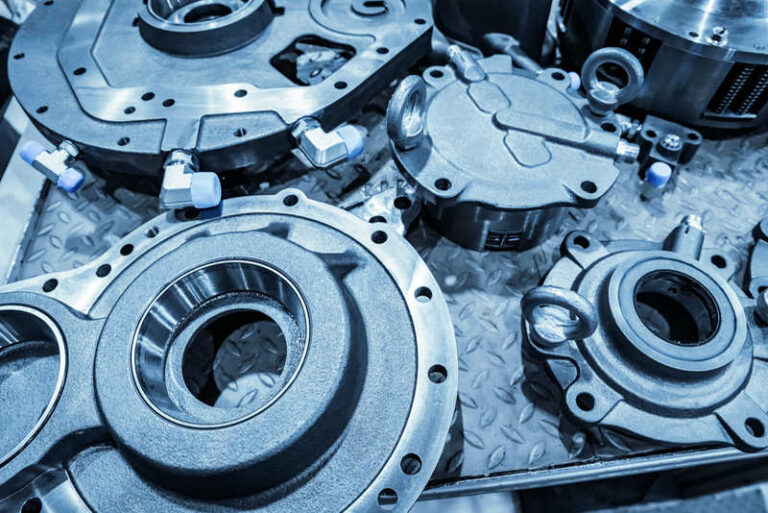

Centrifugal Pumps vs Positive Displacement Pumps

Industrial pumps play a critical role in a wide range of industries, from wastewater treatment to chemical processing, food production, and oil and gas applications. Two primary types of pumps used in industrial settings are centrifugal pumps and positive displacement pumps. Understanding the differences between these two types can help engineers, plant managers, and maintenance personnel choose the best pump for their specific applications.

What Is a Centrifugal Pump?

A centrifugal pump is a hydraulic machine that converts mechanical energy into hydraulic energy using rotational motion. It moves fluid through the system by imparting kinetic energy to the liquid, primarily through an impeller. As the impeller rotates, it increases the fluid’s velocity and pressure, forcing it through the pump’s discharge.

Key Features of Centrifugal Pumps:

- Best for Low to Medium Viscosity Fluids: Centrifugal pumps work best with low-viscosity fluids such as water, light oils, and some chemicals.

- Flow Rate Variability: The output flow rate changes in response to system pressure.

- Efficiency at Higher Flow Rates: These pumps are designed for applications requiring a high and consistent flow rate.

- Continuous Operation: Centrifugal pumps are ideal for continuous-duty applications due to their simple design and efficient operation.

- Lower Initial Cost: They are generally more affordable compared to positive displacement pumps.

Applications of Centrifugal Pumps:

Centrifugal pumps are widely used in industries such as:

- Water treatment plants

- HVAC systems

- Irrigation systems

- Oil refineries

- Food processing

What Is a Positive Displacement Pump?

A positive displacement (PD) pump moves a fixed volume of liquid through repeated mechanical action. Unlike centrifugal pumps, which rely on kinetic energy, PD pumps trap a specific amount of fluid and force it through the discharge system.

Key Features of Positive Displacement Pumps:

- Best for High-Viscosity Fluids: PD pumps excel at handling thick fluids like syrups, sludges, and pastes.

- Constant Flow Rate: The flow rate remains steady regardless of pressure fluctuations.

- Self-Priming Capability: Unlike centrifugal pumps, most PD pumps can handle air pockets and operate efficiently even if the suction line isn’t completely filled with liquid.

- Higher Efficiency at Low Flow Rates: PD pumps perform better than centrifugal pumps when dealing with low flow, high-pressure applications.

- Handles Shear-Sensitive Liquids: They are suitable for fragile fluids that can degrade under high-speed impeller action.

Applications of Positive Displacement Pumps:

PD pumps are commonly used in industries such as:

- Chemical and pharmaceutical processing

- Food and beverage production (e.g., honey, molasses, peanut butter)

- Oil and gas (e.g., metering and injection systems)

- Hydraulic systems

Centrifugal vs. Positive Displacement Pumps: A Side-by-Side Comparison

To provide a clearer understanding of the differences between centrifugal and positive displacement pumps, here’s a direct comparison of their features:

| Feature | Centrifugal Pump | Positive Displacement Pump |

|---|---|---|

| Operating Principle | Uses kinetic energy to move fluid | Moves a fixed volume per cycle |

| Best for Fluid Type | Low-viscosity fluids | High-viscosity and shear-sensitive fluids |

| Flow Rate | Variable based on pressure | Constant regardless of pressure |

| Efficiency | Best at high flow rates | Best at low flow rates and high pressures |

| Self-Priming | Typically requires priming | Usually self-priming |

| Shear Sensitivity | Can damage delicate fluids | Handles delicate fluids well |

| Energy Consumption | Lower at high flow rates | Can be higher due to mechanical operation |

| Common Applications | Water, HVAC, oil refineries | Food, pharmaceuticals, hydraulics |

| Initial Cost | Generally lower | Higher but offers specific advantages |

Real-World Examples and Performance Data

Example 1: Water Treatment Plant

A large municipal water treatment plant relies on centrifugal pumps to distribute millions of gallons of water daily. These pumps efficiently handle low-viscosity liquids at high flow rates, making them the ideal choice for such applications.

Example 2: Food Processing (Peanut Butter Production)

In contrast, a positive displacement pump is used in a peanut butter manufacturing facility. Since peanut butter is highly viscous, a centrifugal pump would be ineffective, while a PD pump ensures consistent volume output without shearing the product.

Performance Data

- Centrifugal pumps can operate at efficiencies of 70-90% for high-flow, low-pressure applications.

- Positive displacement pumps maintain efficiency above 80% even at low flow rates and high pressure conditions.

Choosing the Right Pump for Your Application

When selecting between a centrifugal and a positive displacement pump, consider the following:

- Fluid Viscosity: If handling low-viscosity liquids, use a centrifugal pump. For thicker substances, a positive displacement pump is ideal.

- Flow Rate Needs: If you require a steady flow regardless of system pressure, a PD pump is better. If your application requires high flow rates, go with a centrifugal pump.

- Operating Costs: Centrifugal pumps typically have lower initial costs, while PD pumps provide long-term efficiency for specific applications.

- Self-Priming Requirements: If the pump must operate efficiently even with air pockets, a PD pump is preferable.

- Shear Sensitivity: PD pumps are the better choice when working with delicate fluids that can degrade under high-speed impellers.

Both centrifugal and positive displacement pumps serve vital roles in industrial and commercial applications. Centrifugal pumps are the best choice for high-flow, low-viscosity applications, while positive displacement pumps excel in handling viscous, shear-sensitive, and high-pressure fluids. By understanding their key differences, you can choose the right pump for your system, ensuring maximum efficiency and reliability.

You can also reach out to us with any questions you have or ask for a quote.