Vertical Turbine Pump Suppliers: What You Need to Know

Vertical turbine pumps (VTPs) are among the most reliable and efficient pumping solutions for applications where water or other fluids must be lifted from deep reservoirs, wells, or tanks. Used extensively in municipal water systems, power generation, agriculture, and industrial operations, vertical turbine pumps are engineered for performance and longevity.

As demand for dependable pumping systems continues to grow, choosing the right vertical turbine pump supplier has become a strategic decision. With the global pump market projected to reach $91.7 billion by 2030 (Fortune Business Insights), suppliers play a crucial role in helping industries balance efficiency, durability, and cost-effectiveness.

This article explores the importance of vertical turbine pumps, what to look for in a supplier, key industries that rely on them, and frequently asked questions to guide purchasing decisions.

What Are Vertical Turbine Pumps?

Vertical turbine pumps are centrifugal pumps specifically designed to pump water or other fluids from deep sources. Unlike horizontal pumps, they are vertically oriented, making them ideal for applications with limited floor space or where fluid levels are far below ground.

A standard VTP consists of:

> Pump Bowl Assembly: Located at the bottom of the well or sump, where the impellers lift fluid.

> Column Shaft: Transfers energy from the motor to the impellers through line shafts and bearings.

> Discharge Head: Positioned at the surface, containing the motor, stuffing box, and discharge outlet.

These pumps are highly versatile, capable of handling flows ranging from 50 gallons per minute (GPM) to over 30,000 GPM and heads up to 1,500 feet, depending on the design.

Industries That Rely on Vertical Turbine Pumps

Cities and municipalities use VTPs for potable water supply, raw water intake, and wastewater treatment. Their ability to handle large volumes makes them indispensable in ensuring reliable water delivery.

Agriculture and Irrigation

Irrigation systems depend heavily on turbine pumps to draw water from rivers, canals, or wells. According to the USDA, over 50 million acres of farmland in the United States rely on irrigation, much of which is powered by turbine pumps.

Power Generation

Power plants require turbine pumps for cooling water intake and circulating systems. In nuclear and thermal facilities, these pumps are critical for maintaining operational safety.

Industrial Applications

Industries such as oil and gas, chemical processing, and mining utilize vertical turbine pumps for both process and utility water needs. Their adaptability to handle abrasive fluids and variable flow conditions makes them a top choice.

Key Factors to Consider When Choosing a Vertical Turbine Pump Supplier

Engineering Expertise

A reliable supplier should provide technical expertise in selecting and designing pumps tailored to your operational requirements. Look for suppliers with engineers on staff who can customize materials, impeller types, and shaft configurations.

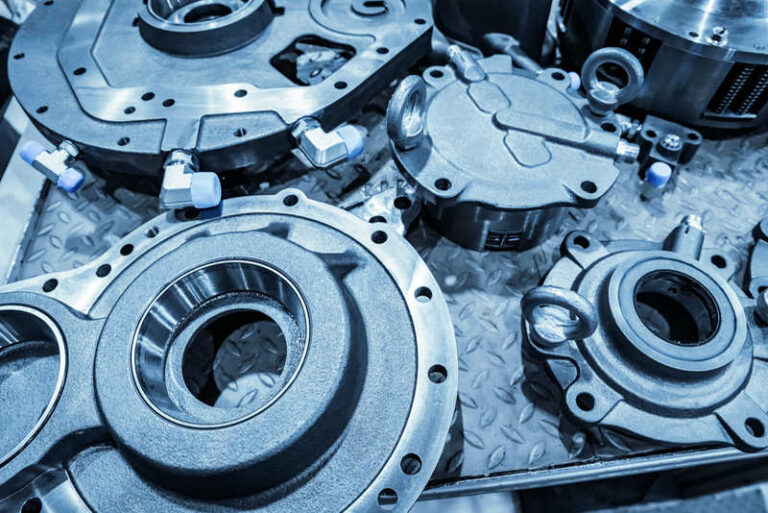

Quality of Manufacturing

High-quality materials such as stainless steel, bronze, or specialized alloys are essential for pumps operating in corrosive or abrasive environments. Suppliers with advanced machining and testing facilities deliver pumps with better reliability and lifespan.

Aftermarket Support

Maintenance and repair services are critical for minimizing downtime. Suppliers that offer spare parts, field service, and preventive maintenance programs provide long-term value.

Proven Track Record

Reputation matters. Suppliers with decades of experience and strong references across industries are generally more dependable. Companies such as Flowserve and Sulzer are recognized globally for their turbine pump expertise (see Flowserve’s vertical turbine pumps for reference).

Customization and Flexibility

Different industries require different solutions. Some suppliers offer custom designs for bowl assemblies, column lengths, and motor drives to meet unique site conditions.

Advantages of Working with Trusted Vertical Turbine Pump Suppliers

Efficiency Gains – Properly matched turbine pumps can reduce energy consumption by up to 20% compared to mismatched systems.

Longevity – With proper maintenance, turbine pumps often operate for 30+ years, making them a long-term investment.

Reliability – Trusted suppliers ensure pumps meet API, AWWA, or NSF standards, guaranteeing compliance with industry regulations.

Operational Safety – Suppliers with strong quality assurance processes minimize the risk of catastrophic failures.

The Role of Denver Industrial Pumps in Supporting Vertical Turbine Pump Projects

At Denver Industrial Pumps, we partner with industry-leading vertical turbine pump manufacturers and provide comprehensive support for system design, installation, and maintenance. Our team specializes in delivering pumps for municipal, agricultural, power generation, and industrial applications.

With decades of experience, we ensure that every pump is tailored to your operational requirements while meeting the highest quality standards. Our focus is not only on supplying pumps but also on providing service, troubleshooting, and spare parts to keep your operations running efficiently.

Frequently Asked Questions About Vertical Turbine Pump Suppliers

1. What is the typical lifespan of a vertical turbine pump?

With proper maintenance, vertical turbine pumps can last 25–30 years or more. Factors such as fluid quality, operating conditions, and material selection influence longevity.

2. How often should turbine pumps be serviced?

Routine inspections should occur at least once per year, while more frequent checks may be required for abrasive or corrosive applications. Bearings, lubrication, and alignment are key maintenance points.

3. Are vertical turbine pumps energy-efficient?

Yes. When properly designed and matched to the application, turbine pumps deliver excellent efficiency, often outperforming submersible alternatives in large-scale water movement applications.

4. Can turbine pumps handle corrosive or abrasive fluids?

Absolutely. Many suppliers offer custom materials like duplex stainless steel or hardened alloys designed to withstand harsh environments.

5. What’s the difference between vertical turbine pumps and submersible pumps?

The main difference lies in motor placement. VTPs use a motor at the surface connected via a line shaft, while submersible pumps have motors located underwater. VTPs are generally easier to service and more efficient for large-capacity systems.

6. How do I choose the right supplier?

Focus on suppliers with proven expertise, robust service support, and a history of successful installations in your industry. Asking for references and reviewing case studies can also help guide the decision.

Vertical turbine pumps are the backbone of many critical industries, from agriculture to municipal water systems. The role of suppliers goes beyond simply selling pumps—they provide engineering expertise, customization, and long-term service that ensures system reliability.

By carefully evaluating supplier capabilities, businesses can secure pumping systems that deliver efficiency, durability, and long-term value. Denver Pumps is proud to serve as a trusted resource for vertical turbine pump projects, helping clients achieve operational excellence through world-class equipment and service.

You can also reach out to us with any questions you have or ask for a quote.