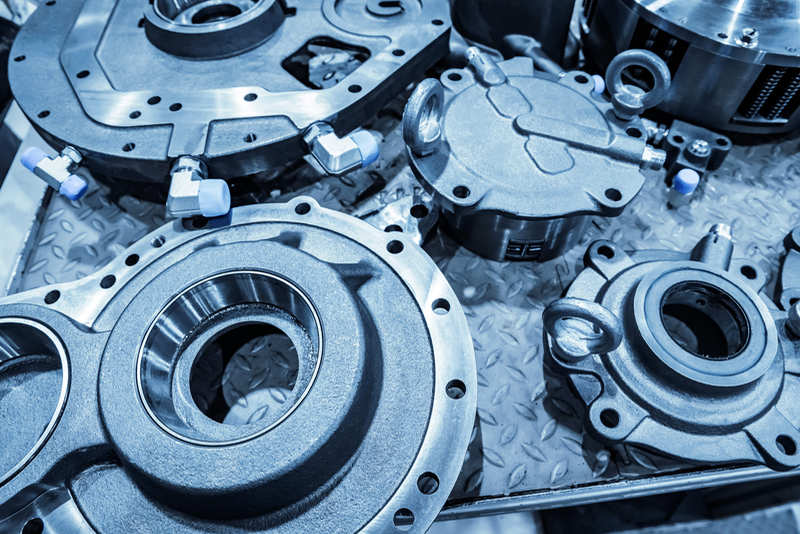

Industrial Pump Parts:

When it comes to industrial operations, pump systems are essential for a wide range of applications, from wastewater treatment to chemical processing and oil refining. In Colorado’s dynamic industrial sector, securing the right pump parts quickly and efficiently can be the key to keeping operations running smoothly. However, obtaining the correct pump parts requires careful consideration of availability, supplier reliability, and product compatibility. This guide provides practical tips for sourcing industrial pump parts in Colorado, including what to look for, questions to ask suppliers, and how to navigate the market effectively.

Understanding Your Pump Part Needs

Before diving into the procurement process, it’s crucial to have a solid understanding of your pump system and the specific parts required. Not all pump systems are the same, and each may require different components depending on the application, fluid type, pressure requirements, and operational environment. Some of the most common industrial pump parts include:

Impellers: Responsible for moving fluid through the pump.

Seals: Prevent leakage and protect the internal components.

Bearings: Support rotating components and reduce friction.

O-rings and Gaskets: Create a seal between static parts.

Casings: Contain the pump mechanism and protect the internal components.

What to Look for When Sourcing Industrial Pump Parts in Colorado

To ensure you’re getting the right parts that meet your operational needs, there are several important factors to consider when sourcing industrial pump components.

1. Compatibility and Specifications

One of the most important considerations is ensuring that the pump parts you order are compatible with your existing pump system. Using incompatible or incorrect parts can lead to operational failures, reduced efficiency, or even system breakdowns. When sourcing parts, ensure you have:

> The model number and serial number of your pump.

> Detailed specifications such as dimensions, materials, and performance requirements.

> The brand and manufacturer information of the original equipment.

> Always verify the specifications of the parts you’re purchasing to ensure they align with your pump’s requirements.

2. Reputable Suppliers and OEM Parts

In Colorado, you’ll find a range of suppliers offering both Original Equipment Manufacturer (OEM) parts and aftermarket components. While aftermarket parts may be cheaper, OEM parts are designed by the pump’s original manufacturer and are guaranteed to fit and function properly with your equipment.

Working with a reputable supplier ensures that you’re getting genuine parts, especially when you’re purchasing critical components like seals or impellers. Established suppliers often provide warranties on OEM parts and offer technical support to help you make the right choice.

3. Availability and Lead Times

Colorado’s industrial sector demands a constant supply of pump parts to avoid costly downtime. Lead times for parts can vary based on the manufacturer and the specific component needed. Some factors to consider regarding availability include:

> Local Stock: Ensure your supplier stocks common parts locally to reduce waiting times.

> Emergency Orders: Check whether the supplier offers expedited or emergency services if you need parts urgently.

> Custom Orders: For less common or specialized parts, verify how long it will take to manufacture and deliver them.

In regions like Colorado where weather conditions or remote locations may impact logistics, having a reliable supplier with strong local connections can make a significant difference in lead times.

4. Supplier Expertise and Technical Support

The best suppliers are those who don’t just sell parts, but offer expert advice and support. Industrial pumps are complex, and sometimes you might need guidance on which parts are best suited for a particular application or how to install them correctly.

Ask about the supplier’s expertise in your specific industry. Do they have experience working with industrial pumps in your sector, whether it’s mining, water treatment, or oil and gas? Can they provide support for installation, troubleshooting, and maintenance? Working with a knowledgeable supplier ensures that you’re not just getting the part, but the assistance needed to keep your operations running smoothly.

Questions to Ask Suppliers Before Making a Purchase

Knowing the right questions to ask can save you time, money, and prevent potential headaches down the road. When contacting a supplier for industrial pump parts, consider asking the following:

Are the parts OEM or aftermarket?

Understanding whether you’re purchasing OEM or aftermarket parts will help you determine the quality and compatibility of the component. OEM parts typically offer a higher level of reliability, while aftermarket parts may be more budget-friendly.

What is the warranty on the part?

Most reputable suppliers offer warranties on their parts. Make sure you understand the terms of the warranty, including the coverage period and any exclusions.

What is the lead time for delivery?

It’s essential to know how long it will take for the parts to be delivered, especially if you need them quickly to avoid production delays.

Do you offer technical support or installation assistance?

Technical support can be invaluable if you run into any issues with installation or operation. Ask if the supplier offers this service and whether it comes at an additional cost.

Are there any additional costs or shipping fees?

Clarify whether the quoted price includes shipping and handling fees, especially if you’re ordering from a supplier outside of Colorado.

Can you provide references or customer reviews?

A reputable supplier should have no issue providing references or directing you to customer testimonials. This can give you confidence in their products and service quality.

What to Be Aware of When Sourcing Pump Parts

While sourcing pump parts may seem straightforward, there are several potential pitfalls to avoid that can impact your operations or budget.

1. Counterfeit or Substandard Parts

One of the biggest risks when purchasing industrial parts, especially online, is receiving counterfeit or substandard components. Counterfeit parts may look identical to OEM parts, but they often fail to meet the required quality standards, leading to premature failure and costly repairs.

To avoid counterfeit parts:

> Only buy from reputable suppliers.

> Look for authorized dealers of the pump’s brand.

I> nspect packaging and markings for signs of tampering or inconsistencies.

2. Hidden Costs

Shipping fees, taxes, and handling charges can quickly add up, especially for large or heavy industrial components. Make sure you’re fully aware of the total cost before making a purchase.

3. Environmental and Safety Regulations

Colorado has strict environmental and safety regulations, particularly in industries like oil and gas, mining, and water treatment. Ensure that any pump parts you purchase comply with local environmental standards, and if you’re working in hazardous environments, make sure the parts meet the necessary safety certifications.

4. Long Lead Times

For specialized parts or components from international manufacturers, lead times can sometimes extend beyond what’s practical for your operation. Plan ahead and maintain an inventory of critical spare parts to mitigate potential delays.

Frequently Asked Questions (FAQs)

Q: How can I ensure I’m purchasing the correct pump part?

A: Always start by checking your pump’s model and serial number. Cross-reference these with the supplier’s catalog to ensure compatibility. When in doubt, contact the manufacturer or supplier directly for assistance.

Q: Can I use aftermarket parts for my industrial pump?

A: Aftermarket parts can be a cost-effective alternative, but they may not always match the quality or fit of OEM parts. For critical components, it’s generally safer to stick with OEM parts to ensure optimal performance and reliability.

Q: What should I do if a part I need is on backorder?

A: If a part is on backorder, ask your supplier for an estimated delivery time and inquire about alternative parts that may be available. In some cases, aftermarket parts or refurbished components can be used temporarily.

Q: How often should I replace industrial pump parts?

A: The replacement frequency depends on the type of pump and its operating conditions. Regular maintenance schedules should be followed, and critical components like seals, bearings, and impellers should be inspected periodically for wear and replaced as needed.

Q: Can I install pump parts myself, or should I hire a technician?

A: For simple components like seals or O-rings, many industrial operations handle replacements in-house. However, for more complex parts or if you’re unsure of the process, it’s advisable to hire a trained technician to avoid potential damage or improper installation.

Securing the right industrial pump parts in Colorado doesn’t have to be a complicated process, but it does require careful consideration of compatibility, supplier reputation, and availability. By asking the right questions, sourcing from reputable suppliers, and being aware of common pitfalls, you can ensure that your operation remains efficient and avoid costly downtime.

Whether you’re looking for OEM parts, aftermarket solutions, or custom components, the key is to stay informed and build strong relationships with suppliers who understand your needs and provide reliable, high-quality products. By taking a proactive approach to sourcing industrial pump parts, you can keep your operation running smoothly and efficiently year-round.

You can also reach out to us with any questions you have or ask for a quote.