MIXERS, HEAT EXCHANGERS & PROCESS EQUIPMENT

WE HAVE YOUR MIXERS, HEAT EXCHANGERS & PROCESS EQUIPMENT SOLUTIONS

Below are some of the manufacturers/products that we service and/or represent. Click on any of the links below to learn more about the products we offer and the companies who manufacture them. If you don’t see the link you are looking for, if you have any questions or would like to place an order, please contact us.

Enhancing Industrial Processes in Denver with Mixers, Heat Exchangers, and Process Equipment

Denver, Colorado, with its booming industrial sector, relies heavily on advanced technologies to optimize various processes. Among the crucial components enhancing industrial efficiency are mixers, heat exchangers, and process equipment. In this article, we will explore the significance of these tools in industrial pump applications, shedding light on their functionality, benefits, and the local landscape in Denver.

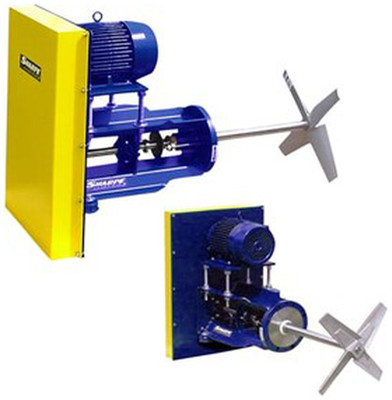

Mixers: Catalysts for Homogeneous Blending

Mixers play a pivotal role in ensuring a homogeneous blend of substances in industrial processes. In Denver’s diverse industrial landscape, mixers find applications across multiple sectors, from food and beverages to pharmaceuticals and chemicals. The key advantage of mixers lies in their ability to promote uniformity, reducing batch variations and enhancing product quality.

Colorado’s Mixers Landscape:

In Denver, businesses are increasingly turning to advanced mixer technologies to streamline their operations. Local industries benefit from a range of mixers, including agitators, static mixers, and paddle mixers, to meet specific process requirements. The use of innovative mixing solutions not only boosts productivity but also aligns with Denver’s commitment to sustainable industrial practices.

Heat Exchangers: Optimizing Thermal Efficiency

Heat exchangers play a crucial role in maintaining optimal temperatures in industrial processes. Denver’s climate, with its temperature variations, necessitates efficient heat exchange systems to ensure consistent production processes.

Advantages of Heat Exchangers:

- Energy Efficiency: In the heart of Denver’s industrial operations, heat exchangers contribute to energy conservation by transferring heat between process streams.

- Cost Savings: The use of heat exchangers leads to reduced energy consumption, resulting in cost savings for Denver’s businesses, aligning with the city’s focus on sustainability and resource efficiency.

Denver’s Heat Exchanger Utilization:

Colorado’s industrial sectors, from manufacturing to petrochemicals, leverage cutting-edge heat exchanger technologies. The local demand for heat exchangers is met by a diverse range of systems, including shell-and-tube, plate, and finned-tube heat exchangers. This diversity ensures that businesses in Denver can choose solutions tailored to their unique operational requirements.

Process Equipment: Driving Industrial Innovation

Process equipment forms the backbone of industrial operations in Denver. From pumps to valves and tanks, these components work synergistically to ensure seamless production processes.

Denver’s Technological Advancements in Process Equipment:

Denver’s industrial landscape is characterized by a commitment to technological advancements. Process equipment manufacturers in the area continuously innovate to provide cutting-edge solutions for various industries. This dedication to progress has positioned Denver as a hub for state-of-the-art process equipment, meeting the evolving needs of the local market.

Synergy with Industrial Pumps:

In the context of industrial pump applications, process equipment collaborates seamlessly with pumps to facilitate fluid movement and control. Denver’s industries benefit from this synergy, ensuring the reliable and efficient operation of their pumping systems.

When searching for mixers, heat exchangers, and process equipment in Denver, businesses aim to find reliable solutions that enhance their operational efficiency. Here are key considerations for those seeking these industrial components in the Denver area:

- Local Suppliers: In Denver’s thriving industrial market, businesses can tap into a network of local suppliers providing mixers, heat exchangers, and process equipment. This ensures quicker delivery times and personalized service.

- Technological Expertise: Denver-based suppliers often boast a high level of technological expertise. Local businesses can benefit from collaborating with experts who understand the unique challenges and requirements of Denver’s industrial landscape.

- Energy-Efficient Solutions: Given Denver’s focus on sustainability, businesses are increasingly seeking energy-efficient solutions. Local suppliers specializing in eco-friendly mixers, heat exchangers, and process equipment align with this environmental commitment.

- Tailored Solutions: Denver’s diverse industries require customized solutions. Local suppliers who offer tailored mixers, heat exchangers, and process equipment ensure that businesses receive components designed to meet their specific needs.

- Support and Maintenance: A crucial aspect of any industrial equipment is ongoing support and maintenance. Denver-based suppliers often provide reliable after-sales service, ensuring the longevity and optimal performance of mixers, heat exchangers, and process equipment.

In the dynamic industrial landscape of Denver, mixers, heat exchangers, and process equipment stand as essential components driving efficiency and innovation. Local businesses can capitalize on these advanced technologies to enhance their production processes while contributing to Denver’s commitment to sustainability and technological advancement. As industries continue to evolve in Denver, the integration of cutting-edge equipment remains paramount for staying ahead in a competitive market.